HOME | home

Iron on the Hearth | Iron, Cast and Forged | Cast Iron Cooking 4 | Copperware | Copper and Brassware 2 | Brass Alcohol Stove | Pipe Smoking | Tobacco the Indian Weed | Women's Pipes | Clay Pipe Collection | Pipes2 | pipes3 | Pipes4 | Pipe Tampers | Early Lighting 1 | Early Lighting 2 | Early Lighting 3 | Early Lighting 4 | Early Lighting 5 | Early Lighting 6 | My Lamps | Center Draft Lamps | Center Draft Lamps II | Center Drafts III | Miners lamps | Matches and Match Safes

Miners lamps

Made by

MONONGAHELA VALLEY

JOHN DUNLAP CO. PITTSBURG PA

This type of lamp was made from the1860s to about 1920

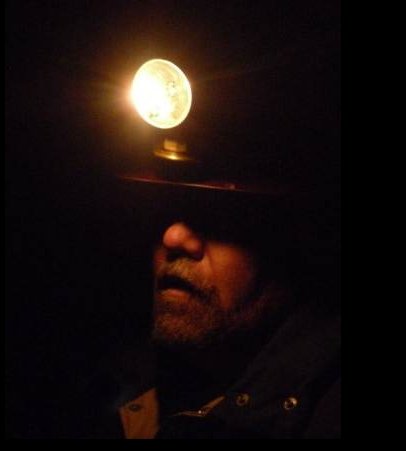

Oil Wick lamps were also commonly referred to as a "Teapot lamps". One type of double-walled ,spout lamp was also known as a "Sunshine Lamp" as it was made to burn Sunshine Wax, a special fuel made by the Standard Oil Company. This waxy fuel was made with normal wax paraffin with a small percentage of mineral oil mixed in. This type of miner's lamp could burn other fuels such as common household oils such as lard, tallow, or fish oil but was designed primarily to burn Sunshine Wax. Conversely, the normal oil wick lamps could not easily use Sunshine Wax as a fuel without the miners doing some tinkering and adaptations to get them lighted and to keep them burning. These lamps are quite amazing when the hook is inserted into the miner's specially designed hat it becomes a amazing way to illuminate the way of the miner. Even after electric lamps were invented these were still in use by many miners. These teapot lamps were used in Scotland and in the USA.

Carbide Lamps

Carbide lamps, also known as acetylene gas lamps, are simple lamps that produce and burn acetylene (C2H2) which is created by the reaction of calcium carbide (CaC2) with water. The conventional format of producing acetylene in a lamp is by putting the calcium carbide in the lower chamber (the generator). The upper reservoir is then filled with water. A threaded valve or other mechanism is used to control the rate at which the water is allowed to drip onto the chamber containing the calcium carbide. By controlling the rate of water flow, the production of acetylene gas is controlled. This, in turn, controls the flow rate of the gas and the size of the flame at the burner, (and thus the amount of light it produces).

This type of lamp generally has a reflector behind the flame to help project the light forward. An Acetylene Gas powered lamp produces a surprisingly bright, broad light. This type of unfocused light works well underground as it improves peripheral vision in the complete dark. The reaction of carbide with water produces a fair amount of heat independent of the flame. In a cold mine a carbide lamp can be used by a miner to provide a heat to help prevent hypothermia.

Auto Lite -Carbide Lamp

The first carbide lamp (mining lamp) developed in the United States was patented in New York on August 28, 1900 by Frederick Baldwin.

The Universal Lamp Company was organized in 1913 by Jacob S. Sherman to produce his Auto-Lite carbide lamps. Sherman first lamp patent was filed in 1914 and awarded as #1,167,942 on Jan. 11, 1916 that would identify the pronounced crown top and concave, urn-shaped design of all Auto-Lite lamp tops for the length of manufacture. By 1918, Sherman had moved the company from Staunton, IL to Chicago. The company continued to expand its product line and in 1933, it purchased the Shanklin Manufacturing Co. and its Springfield, IL plant. An integration of the Auto-Lite and Guy's Dropper lamp design features soon followed. Jacob S. Sherman was also the founder of the Park Sherman Company in Springfield, IL. The company sold miner's supplies (miner's cap lamps, match cases, etc.) and later specialized in things like coin banks and smoking accessories (lighters, cigarette cases, etc). The relationship between Universal Lamp Company and Park Sherman is not altogether clear, but Sherman founded both and operated both. Universal continued to manufacture carbide lamps at the Springfield plant until 1960 when the carbide lamp products were discontinued. Likewise, the Park Sherman Company operated out of Springfield until 1960 when it was sold to a New Jersey company. During the 1913-1960 span of Auto-Lite's cap lamp life, the company produced at least six top design styles, four bottom styles, six cap mounting hooks, three water valve variations, three different water doors, two gas tube variations, at least nine top markings, and at least seven different bottom markings. That's a lot of combinations for a cap lamp that maintained its distinctive looks over those 47 years. Although they produced mainly cap lamps, Auto-Lite did manufacture an 8-hour hand lamp marked Big Boy in combinations of brass and steel and with two different bail designs. The Springfield plant of Universal Lamp Co. has claimed that it produced over 9,000,000 carbide lamps during its operations!

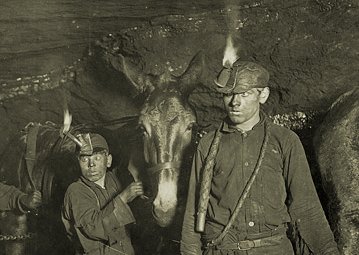

Early Coal Mining in Pennsylvania

This page is dedicated to all the Maxwells who were coal miners in Scotland and in Pennsylvania

The Collier Laddie

Coal mining began in Scotland as early as the 12th century. The development of the steam engine by James Watt in the 18th century began to increase demand for coal. Railway development in the 19th century increased demand for coal further and mines therefore had to be dug deeper. This song was written before deep pit mining or the Industrialization of Scotland. The graphics used in this video represent mining from Burns time to the early twentieth Century. Many Coal miners from Scotland emigrated to the new world and some like my ancestors settled in the coal and steel region of Western Pennsylvania. On this video Alan Reid sings the song Collier Laddie a song by Robert Burns about a young women who loves her coal mining lad.

Alan Reid is a founder member of the Battlefield Band and has been touring the world with this great Scottish group for over 25 years, also singing on all the many albums the band have produced over the years. Indeed many of the songs and tunes that the Battlefield Band have in their repertoire were composed or written by Alan. Here he does a fine Interpretation of The Collier Laddie by Burns.

My Collier Laddie

by Robert Burns

1792

Tune--"The Collier Laddie."

I.

Where live ye, my bonnie lass?

An' tell me what they ca' ye;

My name, she says, is Mistress Jean,

And I follow the Collier Laddie.

My name she says, is Mistress Jean,

And I follow the Collier Laddie.

II.

See you not yon hills and dales,

The sun shines on sae brawlie!

They a' are mine, and they shall be thine,

Gin ye'll leave your Collier Laddie.

They a' are mine, and they shall be thine,

Gin ye'll leave your Collier Laddie.

III.

Ye shall gang in gay attire,

Weel buskit up sae gaudy;

And ane to wait on every hand,

Gin ye'll leave your Collier Laddie.

And ane to wait on every hand,

Gin ye'll leave your Collier Laddie.

IV.

Tho' ye had a' the sun shines on,

And the earth conceals sae lowly;

I wad turn my back on you and it a',

And embrace my Collier Laddie.

I wad turn my back on you and it a',

And embrace my Collier Laddie.

V.

I can win my five pennies a day,

And spen't at night fu' brawlie;

And make my bed in the Collier's neuk,

And lie down wi' my Collier Laddie.

And make my bed in the Collier's neuk,

And lie down wi' my Collier Laddie.

VI.

Luve for luve is the bargain for me,

Tho' the wee cot-house should haud me;

And the world before me to win my bread,

And fair fa' my Collier Laddie.

And the world before me to win my bread,

And fair fa' my Collier Laddie.

The Collier Laddie was communicated by Burns, and in his handwriting, to the Museum: it is chiefly his own composition, though coloured by an older strain.

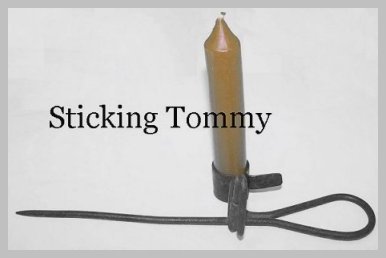

A "sticking tommy" or miner's pick is a candle in a forged holder with a hook to hang on the front of the helmet. The holder also had a point that could be stuck into a crevice in the rock once the miner reached his work station. Candles saw the most use between the 1880s and 1910 in the west and great lakes states in the USA.

|

Links

Our thoughts and prayers are with the families

of the 29 men that lost their lives in the

Upper Big Branch Coal Mine in West Virginia

April 6, 2010

Copyright 2010 , Jim & Beth Boyle, All Rights Reserved

No part of this Webster may be used for any purpose ( including using images )

without written consent from The Rams Horn